JLR Press Archive -

July 16, 2020

1.5 million and counting: Jaguar Land Rover celebrates clean engine manufacturing milestone

- More than 1.5 million Jaguar Land Rover Ingenium engines have now been produced

- The Engine Manufacturing Centre (EMC) houses the full line up of Ingenium powertrain technologies

- New straight-six diesel joins the Ingenium family which also includes Electric Drive Units (EDU) assembled at the Wolverhampton facility, UK

- Innovative manufacturing facility supports the move to electrification and is part of the company’s Destination Zero mission

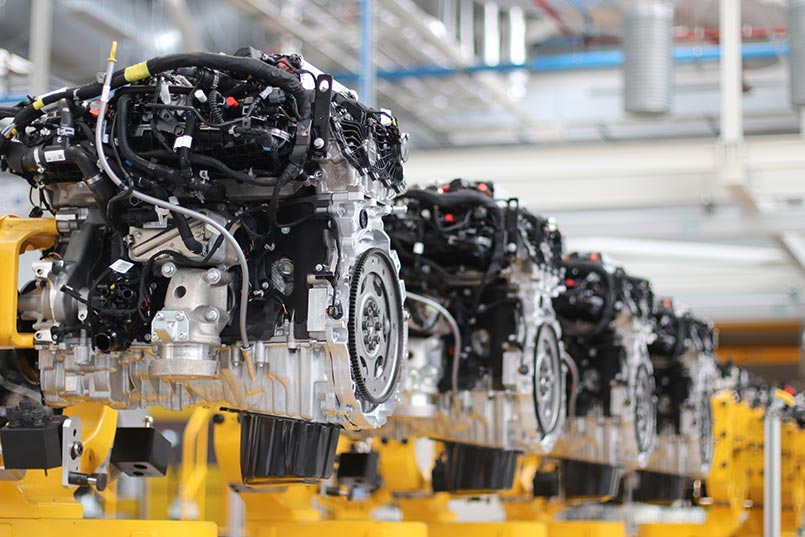

Jaguar Land Rover has now produced over 1.5 million Ingenium engines, as the UK manufacturer celebrates its leading facility adding a new, advanced powertrain offering.

Jaguar Land Rover has now produced over 1.5 million Ingenium engines, as the UK manufacturer celebrates its leading facility adding a new, advanced powertrain offering.

The Engine Manufacturing Centre in Wolverhampton, UK, produces the ultra-efficient Ingenium powertrain family, providing a range of clean and electrified powertrains for all Jaguar and Land Rover models*.

The advanced Ingenium family, which includes a range of clean, refined and efficient diesel, petrol and electrified engines, are built to maximise performance whilst at the same time reducing the environmental impact and running costs for customers. Developed and manufactured in-house in the UK, Jaguar and Land Rover’s all-aluminium Ingenium engine designs are modular, flexible and scalable, with common core technologies.

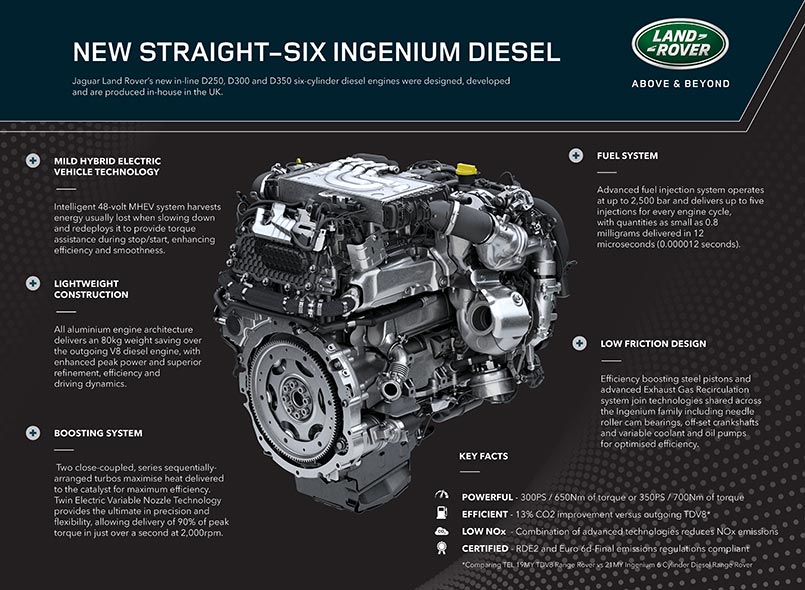

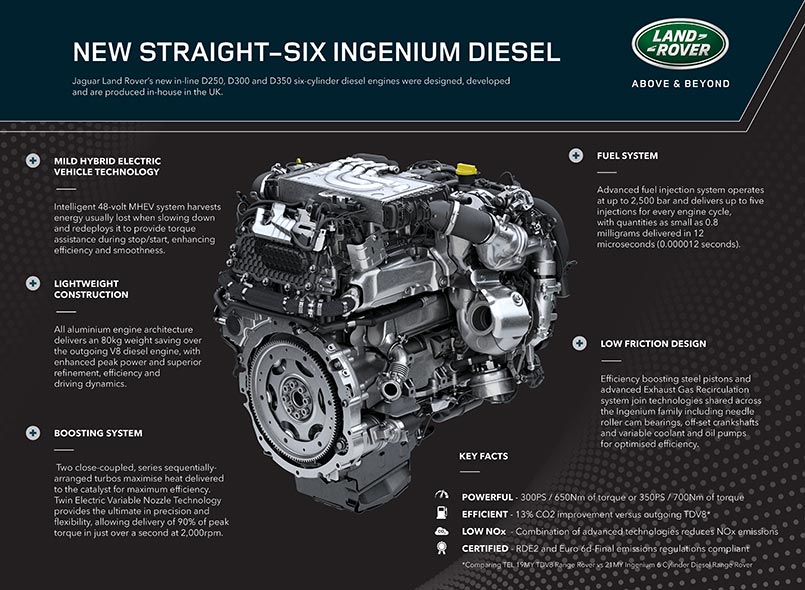

The latest addition to the Ingenium range is the six-cylinder diesel engine, which offers enhanced performance, smoothness and efficiency, powering the new Range Rover and new Range Rover Sport. The advanced in-line Ingenium diesel engine, featuring mild hybrid technology, joins the range of clean and efficient six-cylinder petrol and four-cylinder petrol and diesel engines manufactured at Jaguar Land Rover’s facility in the West Midlands.

The evolving, efficient Ingenium family supports the company’s long-term commitment to reduce vehicle emissions and improve fuel economy across its vehicle range. This is part of its Destination Zero mission and a commitment to reducing emissions and making environments cleaner through relentless innovation.

Jaguar Land Rover will continue to develop its Ingenium technology, continue to advance the electrification of its model line-up and establish a concept hydrogen fuel cell powertrain solution**. The Engine Manufacturing Centre also houses the assembly of Electric Drive Units (EDUs), offering full flexibility between new petrol and diesel engines and EDUs for those customers who want to make the switch from conventional to electrified vehicles.

The Wolverhampton site is complemented by a growing electrification ecosystem in the Midlands, with the innovative and technologically advanced Battery Assembly Centre at nearby Hams Hall assembling PHEV and BEV batteries. Together, they will power the next generation of Jaguar and Land Rover electrified vehicles.

Ken Close, Jaguar Land Rover Powertrain Operations Launch Director, said: “We are experiencing unprecedented demand for cleaner-running vehicles, so it’s more important than ever to deliver clean and efficient engines without compromising on the performance or all-terrain capabilities our customers have come to expect.

“Our Ingenium powertrains offer the very best of both worlds – better fuel efficiency and lower emissions, and even greater torque for a more responsive and engaging drive.”

The Engine Manufacturing Centre supplies engines to Jaguar Land Rover’s global vehicle operations, with a large majority of those powertrain units used in UK based facilities including Solihull, home of the recently announced new Range Rover and new Range Rover Sport.

The latest six-cylinder diesel shares its manufacturing facilities with the six-cylinder petrol engine, which was successfully launched last year. These include machining of the key architecture, cylinder head, cylinder block and crankshaft, as well as the assembly and testing of the engine. The Engine Manufacturing Centre has utilised its extensive modern machining, assembly, test and metrology capability to successfully deliver one of the world’s leading clean diesel engines.

Editors’ notes:

*The EMC provides powertrain options across all Jaguar Land Rover models except the Jaguar I-PACE

**Government announces Advanced Propulsion Centre funding.

www.gov.uk/government/news/735-million-to-boost-green-economic-recovery-in-automotive-sector

For more information about Destination Zero please visit www.jaguarlandrover.com/2019/strategy

About Jaguar Land Rover

Jaguar Land Rover is the UK’s largest automotive manufacturer, built around two iconic British car brands. Land Rover is the world’s leading manufacturer of premium all-wheel-drive vehicles. Jaguar is one of the world’s premier luxury marques, as well as being the first ever brand to offer a premium all-electric performance SUV, the Jaguar I-PACE.

At Jaguar Land Rover we are driven by a desire to deliver class-leading vehicles, providing experiences people love, for life. Our products are in demand around the globe and in 2019 we sold 557,706 vehicles in 127 countries.

At heart we are a British company, with two major design and engineering sites, three vehicle manufacturing facilities, an Engine Manufacturing Centre and soon to be opened Battery Assembly Centre. We also have vehicle plants in China, Brazil, India, Austria and Slovakia. Three of our seven technology hubs are in the UK – Manchester, Warwick (NAIC) and London – with additional sites in Shannon, Ireland, Portland, USA, Budapest, Hungary and Changshu, China.

We have a growing portfolio of electrified products across our model range, embracing fully electric, plug-in hybrid and mild-hybrid vehicles, as well as continuing to offer the latest diesel and petrol engines, giving our customers even more choice.

We are confident that our comprehensive strategy, exciting pipeline of market-leading vehicles and innovative approach to technology and mobility will see us continue to progress towards Destination Zero, our mission to shape future mobility with zero emissions, zero accidents and zero congestion.

Jaguar Land Rover has now produced over 1.5 million Ingenium engines, as the UK manufacturer celebrates its leading facility adding a new, advanced powertrain offering.

Jaguar Land Rover has now produced over 1.5 million Ingenium engines, as the UK manufacturer celebrates its leading facility adding a new, advanced powertrain offering.